Written by Michele Wheat

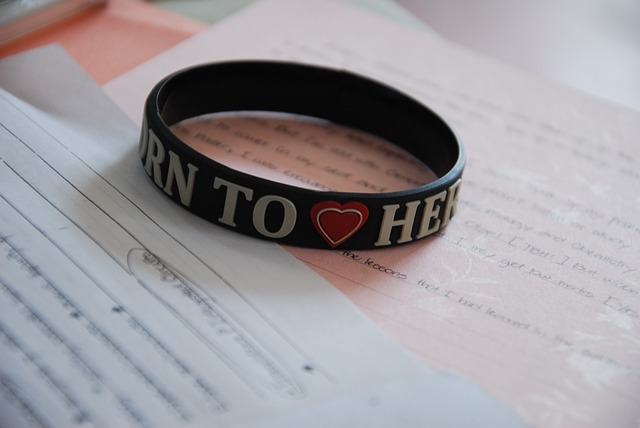

Silicone is all around us, in products as diverse as Silly Putty, Post-it notes, wristbands, contact lenses, and even the soles of the boots that left man's first footprints on the moon. Silicone is a remarkable material that was first commercially produced in the 1940s. A type of synthetic polymer scientifically known as polysiloxane, silicone comes in liquid, soft rubber, and hard solid forms. Silicone is temperature-, flame-, UV-, and ozone-resistant and has low chemical reactivity. It has a tensile strength of between 200 and 1500 psi and rebounds and compresses effectively. It can be formulated to be electrically insulative or conductive. It repels water, yet it is gas-permeable. It is generally nonstick, yet it adheres well to certain specific surfaces, such as glass, and it bonds well with metals. It is hypoallergenic, antimicrobial, and stain-resistant. With its unique array of properties, since its invention, silicone has become an important material in a wide range of industrial and consumer products and applications.

The Composition and Manufacture of Silicone

Silicone's essential component is silicon. Though it is the second most abundant element in Earth's crust, silicon does not occur in its pure form in nature. Rather, it is bound to oxygen in the form of silicon dioxide, or silica, which occurs in nature as quartz. Therefore, in order to make silicone, silicon must first be freed from silica. This is done by heating silica at a high temperature. The resultant product is pure silicon, which, once cooled, is ground into a powder. Silicon powder is combined with methyl chloride and heated once again to form methyl chlorosilane. Methyl chlorosilane is then distilled to separate its various components, including dimethyldichlorosilane, the main building block of silicone. Subsequent catalyzation, condensation, and polymerization of dimethyldichlorosilane produces silicone end products in a multitude of forms, including liquids, solids, pastes, greases, oils, gels, and rubber.

Before There Was Silicone: From Silica to Organosilicon

As with many scientific discoveries, the invention of silicone was not a single eureka moment. Rather, it was the result of the progressive discoveries of a number of scientists over many years. The first essential step in the invention of silicone was the isolation of silicon from silica. This was achieved in 1824 by the Swedish chemist Jöns Jakob Berzelius, one of the founders of modern chemistry. Once silicon was isolated, the next significant step in the invention of silicone was the creation of silicon-based compounds. While working on methods for synthesizing organic compounds, French chemist Charles Friedel and American chemist James Mason Crafts created the first known organosilicon compound, tetraethylsilane, in 1863. Over the next decade, their work in organosilicon chemistry was advanced by German chemist Albert Ladenburg.

The Commercial Production of Silicone

The production of silicone as it is known today is predominantly the result of the work of two pioneering scientists, British chemist Frederic Stanley Kipping and American chemist James Franklin Hyde. As a professor in the chemistry department at the University of Nottingham, Kipping dominated organosilicon research from 1899 until his retirement in 1936. He isolated a number of pure silicon monomers and coined the term "silicone," but he envisioned no practical use for the material. It fell to Hyde to be the first to produce commercial silicone. Hyde was hired in 1931 by Corning Glass Works (now known as Corning Inc.) to develop a material that would allow Corning to compete with newly invented transparent plastics. Hyde used his knowledge of Ladenburg's and Kipping's work to develop a substance that combined the best elements of glass and plastics. Hyde's work laid the foundation for contemporary silicone polymer production and led to the creation of hundreds of useful products, from material used for taking dental impressions to silicone caulk, many of them invented by Hyde himself. Thus, Hyde earned the nickname "the father of silicones."

Silicone Today

Today, silicone is everywhere. Silicone is widely used in consumer cookware and throughout the food and beverage industry. Silicone is omnipresent in electronics and construction in the form of sealants, coatings, and adhesives. Silicone is used to coat spark plugs and seal air bags in automobiles. It's also used in aircraft manufacturing and maintenance and as the rubber in spacesuits. Silicone rubber is commonly used in medical tubing and in products like prosthetic heart valves. Hair-care products also contain silicone, and it's a basic ingredient in cosmetics, making products soft, shiny, and easy to spread. Silicone is used in fabric care and textile manufacturing as a fabric softener and a waterproofing agent. Silicone is also used in the manufacture of toys and jewelry, including the colorful wristbands used to show support for a cause or an organization.